We are dedicated to enhancing the efficiency and effectiveness of your industrial processes. Our mission is to deliver tailored solutions that optimize and streamline your operations through advanced automation technologies. Our comprehensive suite of core activities includes:

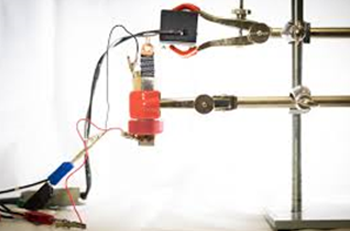

We excel in creating and implementing robust control systems that manage industrial processes. Our expertise covers the selection and configuration of both hardware and software to ensure precise control of your machinery and equipment.

Our team specializes in developing and maintaining PLC programs that are essential for controlling various machinery and processes, ensuring seamless operation and reliable performance.

We design and implement intuitive interfaces that facilitate effective interaction between operators and automated systems, enhancing user experience and control.

Our services include installing and configuring Supervisory Control and Data Acquisition (SCADA) systems that offer comprehensive monitoring and control of your industrial processes, ensuring operational transparency and efficiency.

We select and integrate advanced sensors and actuators to measure critical variables such as temperature, pressure, and flow, and to control physical processes with precision.

To meet the highest standards, we ensure that all automated systems are properly calibrated and rigorously tested, guaranteeing optimal performance and compliance with operational requirements.

We design and implement sophisticated robotic systems for various tasks, including assembly, welding, painting, and material handling, to improve productivity and precision.

Our team develops custom software applications for managing and controlling automated systems, incorporating real-time data analysis and process optimization to drive efficiency.

We establish reliable communication networks and protocols to ensure seamless data exchange between different components of your automation system, enhancing overall system connectivity.

We implement advanced systems for collecting, analyzing, and interpreting data from multiple sources, empowering you with valuable insights to improve decision-making and operational efficiency.

Our commitment extends to providing ongoing maintenance and support, addressing any issues promptly to ensure the continuous performance of your automated systems.

We prioritize safety by developing protocols and systems that protect both personnel and equipment, including emergency shutdown systems and safety interlocks.

We ensure that new automation solutions integrate smoothly with your existing machinery, processes, and IT systems, preserving the integrity of your operations.

We offer comprehensive training for operators and engineers, equipping them with the skills needed to effectively use and maintain automated systems, complemented by ongoing technical support.

Leveraging automation, we analyze and refine manufacturing processes to boost efficiency, minimize waste, and enhance quality control.

We utilize Internet of Things (IoT) technologies to connect and manage industrial devices and systems, facilitating remote monitoring and control for greater flexibility and oversight.